DENMARK, November 2017

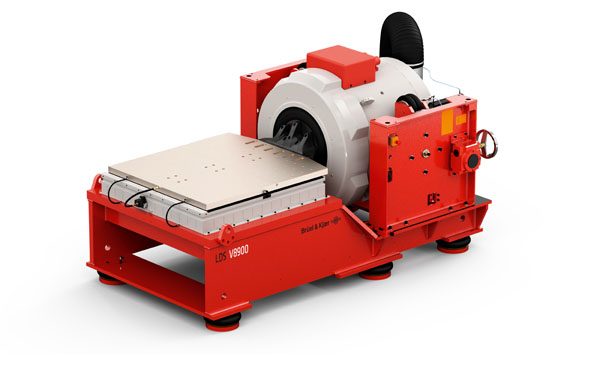

Shock testing is an integral requirement of any automotive test environment, with a growing demand for components and sub-assemblies to be tested under the recognized 100 g-11 ms specification from the GMW 3172 standard. Typically, a very large system would be needed in order to achieve the high voltages needed to perform this test with large payloads; however, the new LDS V8900 with the XPA-K amplifier, developed by Brüel & Kjær VTS, fulfils the requirements of this specification for payloads up to 55 kg.

Technical performance is a key factor in any shaker decision and test specification, but increasingly, energy management is a driving factor. The V8900 and XPA-K combination helps companies satisfy the ISO 50001 directive and the development of an energy management system (EnMS) by intelligently monitoring and selecting the most efficient power usage profile for the tests being run – all without compromising test performance. This makes the V8900 and XPA-K combination the perfect accompaniment to any test environment.

The new features available on the V8900 and XPA-K system combination, coupled with its already impressive specification, include:

- 80 kN sine force

- 101.6 mm displacement

- 3,000 kHz max frequency

- 3 kNm overturning moment restraint

For more information on the V8900 air-cooled shaker visit www.bksv.com/V8900 or contact Brian Zielinski-Smith (Product Manager) at Brian.zielinski-smith@bksv.com.

▽

▽

English

English

Français

Français

Nederlands

Nederlands